Medicinal aluminum foil composite film

Using medicinal grade materials, produced in a 100000 level purification workshop, ensuring hygiene, safety, and stable quality

Tag:

Classification:

Product Details

|

|

|

|

Medicinal aluminum foil composite film is a high-performance packaging material specially used in the pharmaceutical field.

1. Material composition and structure

Aluminum foil layer

Aluminum foil is an important component of the composite film. Aluminum foil has excellent barrier properties and can effectively block external factors such as oxygen, water vapor, and light. For medicines, this can prevent the medicines from getting damp, oxidized, and deteriorating, thereby extending the shelf life of the medicines. The metallic properties of aluminum foil also give the packaging a certain strength, which helps to protect the medicines from physical damage during transportation and storage.

Composite layer

In addition to the aluminum foil layer, the composite film also contains other composite layers. For example, there will be an inner layer that is in direct contact with the medicine, which is usually made of plastic materials that meet pharmaceutical standards, such as polyethylene (PE). This layer has good chemical stability, does not react with the medicine, and has a certain flexibility, which is convenient for packaging and taking the medicine. The outer layer may have a protective layer or a printing layer. The protective layer can enhance the wear resistance and puncture resistance of the entire composite film, and the printing layer is convenient for marking relevant information of the medicine on the packaging, such as name, specification, usage, shelf life, etc.

2. Functional characteristics

High barrier property

As mentioned above, high barrier property to oxygen, water vapor and light is one of its most important characteristics. This property enables it to create a relatively stable storage environment for drugs, especially for drugs that are sensitive to the environment, such as some vitamin drugs that are easily oxidized, antibiotic drugs that are sensitive to humidity, etc.

Safety

Due to the strict production in accordance with the standards of pharmaceutical packaging, the material selection and production process of the entire composite film are strictly controlled to ensure that no harmful substances are released when in contact with drugs, and the safety and effectiveness of drugs are guaranteed.

Convenience

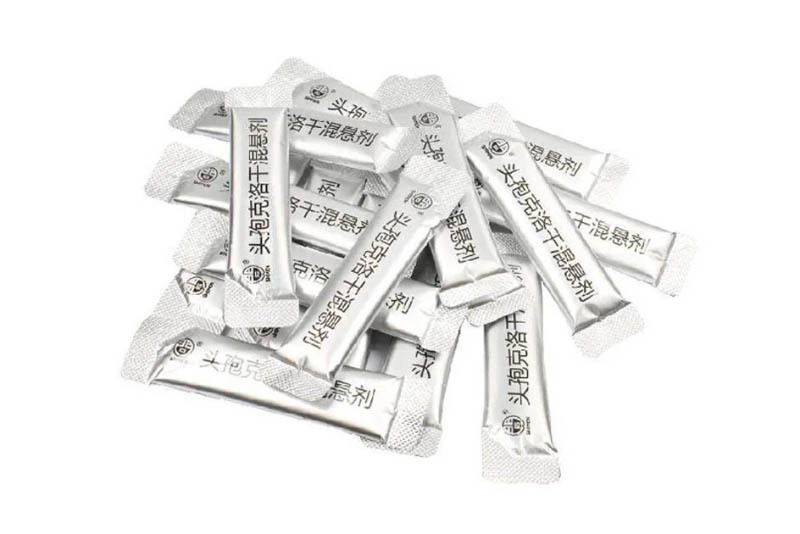

Medicinal aluminum foil composite film is easy to process and can be made into various shapes and specifications of packaging according to the packaging requirements of different drugs, such as blister packaging for tablets, strip packaging for capsules, etc., which is convenient for the production, storage, transportation and sales of drugs.

3. Application scope

Oral drug packaging

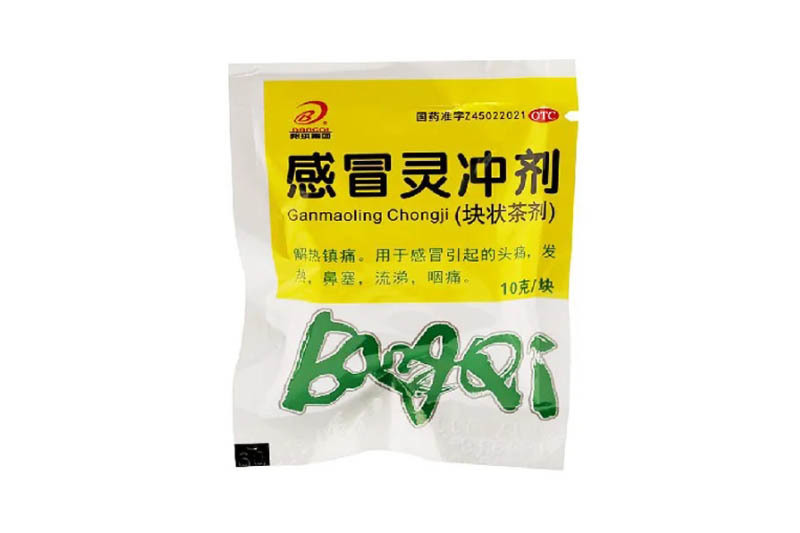

It is widely used in the packaging of various oral drugs, including tablets, capsules, pills, etc. It can effectively protect the quality of drugs and facilitate patients to identify and take drugs.

External medicine packaging

For some external medicines such as ointments and gels, Medicinal aluminum foil composite film can also provide good packaging protection to prevent the medicines from being contaminated and deteriorated.

Material composition: PET/AL/PE

Thickness: Single side thickness of 7.5 silk or more (AL can use double zero 7 or double zero 9), customized according to customer requirements

Product features:

1. Using medicinal grade materials, produced in a 100000 level purification workshop, ensuring hygiene, safety, and stable quality

2. Gravure printing, rich in printing colors (1-8 color printing), clear pattern hierarchy, beautiful design

3. Aluminum foil composite film has excellent oxygen resistance, light avoidance, and sealing properties, ensuring the shelf life of the product

4. Has good stiffness and flatness, excellent chemical stability and corrosion resistance

5. Suitable for gamma ray sterilization

6. Low temperature heat sealing anti pollution, heat sealing temperature 110-130 ℃, suitable for high-speed automatic packaging machines.

Similar products

ONLINE MESSAGE

Note: Please be sure to fill in the information accurately and maintain smooth communication. We will contact you as soon as possible